I realize that only a few of you care, so I’m providing a picture for those who don’t.

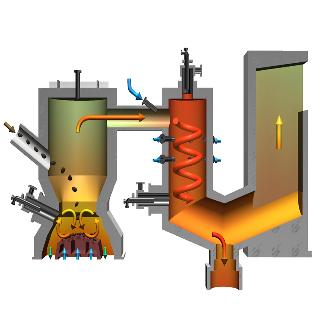

I realize that only a few of you care, so I’m providing a picture for those who don’t."Spouted fluidized bed coaters are used for applying coatings to tri-isotropic (TRISO) nuclear fuel particles for the advanced high temperature gas reactor (HTGR) and other Generation IV nuclear power reactors. The purpose of this project is to scale up coaters to production size by collecting detailed experimental measurements from the currently used 50-mm spouted bed coaters, intermediate size spouted beds (84 and 150-mm), and selected candidates for production scale coaters. In order to supply the required fuel particles for commercial reactors, 150 to 300-mm diameter coaters need to be designed. However, scale-up of the fluidization processes with chemical reactions poses unsolved problems. These processes are highly nonlinear, sensitive to boundary conditions and disturbances, and exhibit transients and unstable hydrodynamics. Further, the larger coaters will inevitably require distributors that are more sophisticated than the typical conical bottom.

Research objectives are to:

1. Design and fabricate fluidized beds with changeable nozzles, distributors, and other components.

2. Develop LabVIEW software for operation, control, data collection/synchronization, data archiving, and feedback control.

3. Collect detailed experimental data, including local gas velocities and signal conditioned high-speed inlet pressure measurements (1000 samples/second).

4. Develop an experimental matrix of parameters, which may include: bed diameter, cone angle and throat diameter, selected distributors, bed load (amount of particles), type of gas, gas flow rate, as well as particle properties (surface characteristics, sphericity, size distribution, density, bulk density).

5. Conduct image analysis using synchronized video from two cameras for spout shape (height and diameter), Poincaré sections for particle circulation, resident times distributions, and wall boundary conditions.

6. Develop correlations for spouted bed characteristics, such as minimum spouting velocity, bed pressure drop, spout shape, and scale-up.

7. Develop new measurement techniques and implement maturing technology, such as the ability to measure local particle flux, local particle momentum distribution, use fiber-optic probes for circulation studies, and local void fraction measurement.

8. Support instrumentation and control of hot coaters and address data measurement in the harsh coating environment of high temperature (2000 K) and chemical vapor deposition (coats everything).

9. Apply chaos and nonlinear dynamics concepts for process monitoring and control (hydraulic state, distributor restrictions, wall agglomerates, free agglomerates, abnormal events)."

2 comments:

?

Every once in a while, friends ask me what I do. I don't want to insult them by dumbing things down, but I don't want to bore them by revealing too much. I thought this post was good middle ground.

Post a Comment